- Navigation

- Column

ADD: Jisuo Town, Jixiang Industrial Park, Tengzhou City, Zaozhuang City, Shandong Province

TEL:13793739155

WEB:www.jhhqsic.com

E-MAIL:jhhqzwx@163.com

Application

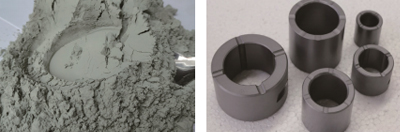

Silicon Carbide for Precision Ceramics

Special ceramics generally use high-purity micro-nano materials, and the raw materials used are required to be: 1. Small particle size, narrow particle size distribution range, or a certain particle size gradation. 2. The particles are equiaxed, with few agglomerated particles and low agglomeration strength. 3. The chemical purity and chemical composition uniformity can be controlled, and the particle size D50 is less than 0.8 microns, and the maximum particle size does not exceed 5 microns. Silicon carbide, mainly a-type silicon carbide, is used as the raw material to ensure the thermal stability and corrosion resistance of precision ceramics, with concentrated and uniform particle size distribution, high yield rate, stable shrinkage, and can achieve the ideal density effect. The relevant indicators are far superior to similar products.

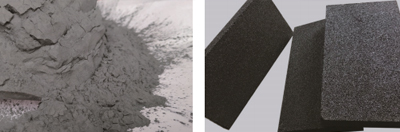

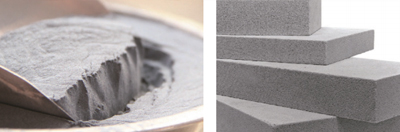

Silicon carbide for thermal insulation materials

Thermal insulation materials generally refer to materials with a thermal coefficient less than or equal to 0.12, including thermal insulation boards, nanoporous thermal insulation boards, etc. At present, the commonly used specifications for customers are mainly 5um or finer silicon carbide powder.

Silicon carbide powder has passed Rohs and Reach certification, does not contain harmful substances, can improve the thermal insulation performance of the product, and has the characteristics of energy saving and environmental protection.

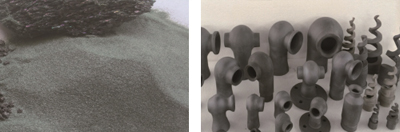

Reaction bonded silicon carbide

Green silicon carbide powder is the main raw material for reaction sintering ceramics: it can be used for casting, extrusion and pressing processes. The main production process is air flow milling, with a content of more than 99.2%. It has the advantages of good particle shape, strong fluidity and reasonable particle size distribution, and is widely praised by downstream customers. Applicable products include silicon carbide nozzles, kiln furniture, desulfurization, electricity, seals, grinding cylinders, etc.

Pressureless sintered silicon carbide

Silicon carbide for pressureless sintering is made by wet grinding. It has high powder purity, narrow particle size distribution, good fluidity and strong stability. The products produced have the characteristics of high density, high hardness, wear resistance and corrosion resistance. They are widely used in seals, bulletproof equipment, heating plates, pumps and valves, new energy, scientific research, national defense and military fields.

Recrystallized Silicon Carbide

Silicon carbide RS07 and RS100 are mainly used for the production of recrystallized silicon carbide ceramics. The processing technology is grinding modification and airflow + shaping. Required bulk density: above 1.75, coarse and fine mixed filling.

Product features: high bulk density, good fluidity, strong stability, can improve product density, wear resistance and corrosion resistance, widely used in modern kiln tools, electrical porcelain, sanitary ceramics, daily porcelain, grinding wheels, metallurgy and other industries with excellent performance.

Silicon carbide powder for DPF

The automotive particulate filter (DPF) is made of high-purity silicon carbide powder purified by a special process, and is made by mixing, refining, sinking, floating, molding and firing according to the formula. The product has a wall-flow structure, and the filter body is a multi-channel honeycomb. The parallel channels are blocked alternately, so that the particle exhaust capture and purification effect reaches more than 99.6%, leading the international advanced level.

Silicon carbide powder for non-stick pan

Based on the use of many customers and cooperation with major scientific research institutions, we have launched silicon carbide powder for non-stick pan coating, which is resistant to high temperatures of 1800 degrees, more corrosion-resistant, non-toxic, healthy and environmentally friendly. In the coating of non-stick pans, silicon carbide powder can form a hard protective layer, effectively reducing the friction between food and the pan surface, thereby providing better non-stick performance, so that non-stick pans can be used under high temperature conditions without damage. The product has passed Rohs and Reach tests and meets environmental protection requirements.

Silicon Carbide for Silicon Carbon Rod

Silicon carbon rods are made of high-purity green hexagonal silicon carbide as the main raw material, processed into blanks according to a certain material ratio, and sintered at 2200°C high temperature siliconization recrystallization to produce rod-shaped or tubular non-metallic high-temperature electric heating elements. The normal operating temperature in an oxidizing atmosphere can reach 1450°C. The product has high temperature stability, corrosion resistance and wear resistance, and can be used continuously for up to 2000 hours.

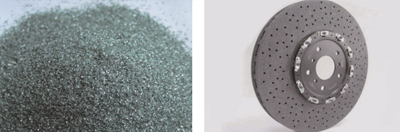

Silicon carbide for brake pads

Silicon carbide micropowder for brake pads has high purity and hardness, and is a high-quality raw material for silicon carbide ceramic brake pads. Silicon carbide ceramic brake pads are resistant to high temperature, high strength, oxidation, corrosion and impact. Compared with steel brakes, carbon ceramic brakes have obvious advantages, such as: longer service life (up to 300,000 kilometers), stronger braking performance (high temperature resistance), lighter weight (the weight is more than half lighter than traditional brake discs of the same size), etc.

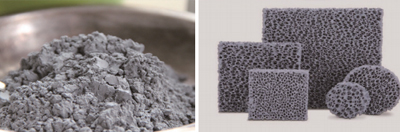

Silicon Carbide for Foam Ceramic

Silicon carbide (SIC) ceramic foam filter has excellent strength and resistance to high temperature impact and chemical corrosion. It can be used at a temperature of 1500°C and can effectively filter impurities and non-metallic inclusions in metal liquids, while also improving gas emissions during metal flow and solidification. It is used in the fields of molten metal filtration, high-temperature flue gas treatment, chemical carriers, solid heat exchangers and special fillers.

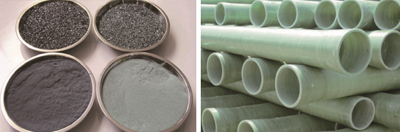

Silicon Carbide for FRP

Silicon carbide for FRP has the advantages of high temperature resistance, corrosion resistance, high hardness, light weight, high strength and good thermal conductivity, and is suitable for manufacturing high temperature resistant equipment, pipelines and chemical containers.

Its high temperature stability and corrosion resistance make it an ideal material choice. At the same time, silicon carbide has good wear resistance and thermal conductivity, which can improve the service life and efficiency of equipment. Therefore, silicon carbide for FRP is widely used in the industrial field.

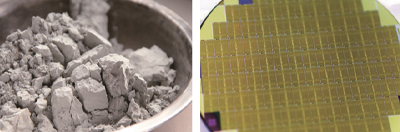

Silicon Carbide for Ceramic Substrates

Silicon carbide ceramic substrates play an important role in the field of power electronics. Compared with silicon materials, silicon carbide has a more stable crystal structure and a wider energy band width. Its maximum operating temperature can reach 600°C, and its breakdown field strength is more than ten times that of silicon. Silicon carbide devices have higher blocking voltage and lower conduction loss. Therefore, the blocking voltage of power devices using silicon carbide ceramic circuit boards is much higher than that of silicon devices, and at similar power levels, the conduction loss of silicon carbide devices is much smaller than that of silicon devices.

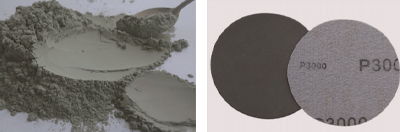

Silicon carbide for coated abrasives

Silicon carbide for coated abrasives is a commonly used abrasive material, such as abrasive belts, emery cloths, sandpaper, etc. Silicon carbide has the advantages of high hardness, good wear resistance, and strong chemical stability, which can effectively improve the grinding efficiency and processing quality of abrasives. In the preparation process of coated abrasives, silicon carbide particles will be evenly distributed on the base material to form an abrasive layer, thereby achieving efficient grinding and processing of workpieces.

Silicon Carbide for Foam Ceramic

Foamed ceramic insulation board is made of clay tailings, ceramic fragments, adulterated materials, etc. as the main raw materials. Silicon carbide is added mainly to play a foaming role. It is a high-porosity closed-cell ceramic material sintered at high temperature. Silicon carbide powder for foamed ceramics has uniform color and reasonable particle size distribution: it can be used in different product formulations and production processes; the addition ratio is 0.3%-0.5%, the foaming pores are uniform and the air permeability is good.

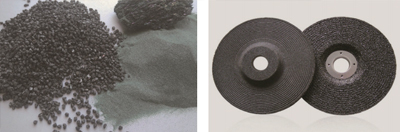

Silicon Carbide for Abrasives

Silicon carbide for abrasives and grinding tools mainly includes black and green silicon carbide granular sand and micro powder in various models and specifications such as 8#-6000#. The raw materials are calcined in a high-power resistance furnace with high power and good purity to ensure quality. The processing equipment includes air flow mill, shaping machine, dry and wet ball mill, Raymond mill, etc. The production process is processed according to user needs to ensure particle shape, less impurities, no doping, and less dust. After ultrasonic screening and water washing, it is ensured that there is no other dust in the material.

Silicon carbide for polishing and grinding

Silicon carbide is very hard, has excellent thermal and electrical conductivity, and is resistant to oxidation at high temperatures. It is widely used in the silicon carbide grinding and polishing industry: mainly used for glass polishing, stainless steel polishing, jade and gem polishing, steel, electronics, tool casting, refractory materials, aerospace and national defense, construction and road construction, denim sandblasting, beauty tools, hardware grinding, and is also suitable for the manufacture of ceramic abrasive blocks, grinding tools and grinding wheels.

Silicon Carbide for Ceramic Membranes

Silicon carbide ceramics are known as the future filtration substrate and are currently the most advanced membrane separation materials in the world. Both the support layer and the filter layer are made of high-purity silicon carbide and are sintered at high temperatures. Because silicon carbide ceramics have the characteristics of acid and alkali resistance, high temperature resistance, high mechanical strength, strong material, safe material, and low isoelectric point, the silicon carbide membrane produced has good filtration effect, anti-pollution, strong material, and maximum flux. The advantages of silicon carbide membrane in material structure determine its advantages in process technology.