Juhe Global New Materials

Harnessing the power of crystal to build an industrial foundation

Silicon carbide material solution practitioner

Quality lies in refinement, cooperation lies in trust. Customers give their feelings to Juhe Global, and we will definitely present you with high-quality solutions.

Black silicon carbide particle size sand

Green silicon carbide particle size sand

Green sic overflow and siphon powder

Pressureless sintering powder

Product

Complete industrial chain and diversified product structure

Perfect industrial chain,diversified product structure

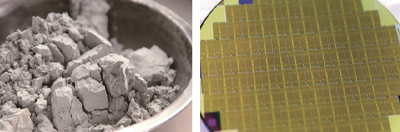

Black silicon carbide is a non-metallic mineral product produced at a high temperature of more than 1800 degrees Celsius with quartz sand (SIO2) and anthracite or petroleum coke (C) as basic raw materials. It has the characteristics of high hardness, small expansion coefficient, brittleness, good thermal conductivity, etc. It is made through crushing, impurity removal, pickling, washing, drying and screening. It has high cleanliness, high purity, high content, good particle size and shape and excellent sharpness. It is widely used in abrasives, grinding of electronic products, refractory materials, special ceramics, foam ceramics, coating plastic addition and modification, auto parts, military aviation, deoxidizer for steelmaking, etc.

CP black silicon carbide is made of petroleum coke and high-quality silica as the main raw materials, and is smelted at high temperature in a resistance furnace. The smelted crystals are of high purity, high hardness, and are composed of α-type hexagonal crystals. After personalized crushing, shaping, pickling, alkali washing, fine classification and other special processes, CP sand has a high concentration, cleanliness and excellent hydrophilicity, and is a special material for coated abrasives.

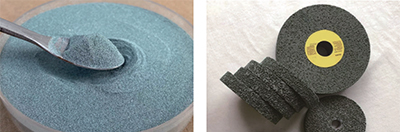

Green silicon carbide is made of petroleum coke and high-quality silica as the main raw materials, and is smelted at high temperature in a resistance furnace. The smelted crystals are of high purity and high hardness. They are hexagonal crystals, and their hardness is second only to diamond. From a chemical point of view, they are very stable at room temperature.

After crushing, impurity removal, pickling, washing, drying, and screening, it has high cleanliness, high purity, high content, good particle size shape and excellent sharpness. It is an ideal material for wire cutting, grinding, polishing, sandblasting, coating, industrial castings, etc. of high-hardness materials.

The main features are: stable quality, good crystallization, high surface cleanliness, no large particles, low fine particle content, concentrated particle size distribution, high grinding efficiency, suitable for various grinding processes, uniform surface of the processed workpiece, no scratches

Application

Complete industrial chain and diversified product structure

Perfect industrial chain,diversified product structure

Recrystallized Silicon Carbide

Based on the use of many customers and cooperation with major scientific research institutions, we have launched silicon carbide powder for non-stick pan coating, which is resistant to high temperatures of 1800 degrees, more corrosion-resistant, non-toxic, healthy and environmentally friendly. In the coating of non-stick pans, silicon carbide powder can form a hard protective layer, effectively reducing the friction between food and the pan surface, thereby providing better non-stick performance, so that non-stick pans can be used under high temperature conditions without damage. The product has passed Rohs and Reach tests and meets environmental protection requirements.

Silicon carbide powder for non-stick pan

Based on the use of many customers and cooperation with major scientific research institutions, we have launched silicon carbide powder for non-stick pan coating, which is resistant to high temperatures of 1800 degrees, more corrosion-resistant, non-toxic, healthy and environmentally friendly. In the coating of non-stick pans, silicon carbide powder can form a hard protective layer, effectively reducing the friction between food and the pan surface, thereby providing better non-stick performance, so that non-stick pans can be used under high temperature conditions without damage. The product has passed Rohs and Reach tests and meets environmental protection requirements. This is a test text, click the “Edit” button to change this text.

Silicon Carbide for Ceramic Substrates

Silicon carbide ceramic substrates play an important role in the field of power electronics. Compared with silicon materials, silicon carbide has a more stable crystal structure and a wider energy band width. Its maximum operating temperature can reach 600°C, and its breakdown field strength is more than ten times that of silicon. Silicon carbide devices have higher blocking voltage and lower conduction loss. Therefore, the blocking voltage of power devices using silicon carbide ceramic circuit boards is much higher than that of silicon devices, and at similar power levels, the conduction loss of silicon carbide devices is much smaller than that of silicon devices.