- Navigation

- Column

High density silicon carbide sand, micro powder

Product Information

The company’s silicon carbide shaping equipment with independent intellectual property rights produces high-density silicon carbide with high purity, high activity, smooth surface, good shape, concentrated particle size distribution, and easy infiltration. It is widely used in chemical, metallurgical, wear-resistant industries, ceramics, industrial high-temperature kilns and other industries.

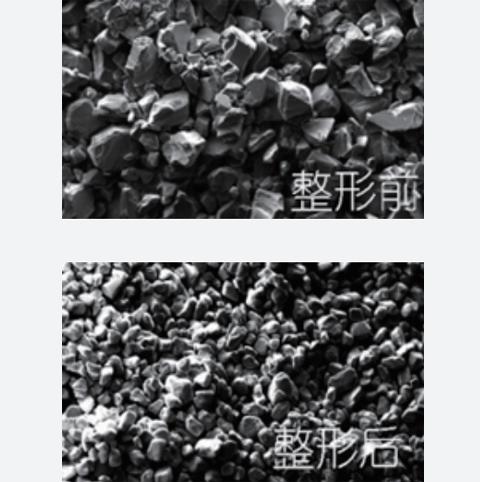

In powder engineering, mechanical grinding is mainly used for powder crushing, while the grinding and crushing force used for powder shaping cannot be too strong, otherwise the powder particles will be crushed, resulting in particle shaping failure. By adjusting the grinding process parameters, the silicon carbide powder particles are softly rubbed in the mill to grind away the irregular parts of the particles.

According to the analysis of the right figure, the crushing effect on the powder particles is basically in the form of falling and throwing. Therefore, the use of this method for particle shaping should minimize the crushing effect of the equipment on the material particles, increase the grinding effect between the grinding medium and the silicon carbide powder particles, and in this way realize the shaping of the silicon carbide powder particles.

Research shows that the application of mechanical grinding technology to shape powder is affected by the following process parameters: mill speed, grinding media filling, grinding media and material ratio, grinding media size, slurry solid content and grinding time, etc. The whole process is adjusted by adjusting various process parameters, on the one hand to ensure that the powder particles are not broken, on the other hand, the irregular parts of the silicon carbide powder particles are slowly ground off through grinding.

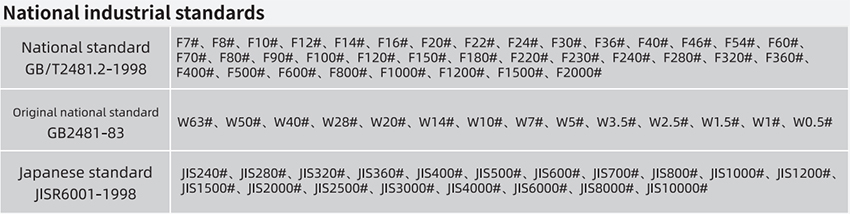

National Industrial Standards

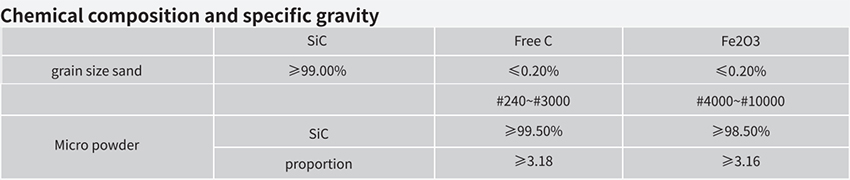

Chemical composition and specific gravity

- Bulk density determination:GB/T20316.1-2009;GB/T20316.2-2006/ISO9136-2:1999

- Particle size distribution method:GB/T2481.1-1998/ISO8486-1:1996;GB/T2481.2-2009

- Magnetic material determination method:JB/T6570-2007

- Chemical detection methods:GB/T3044-2007